360-Grad-Logistik-Expertise

LOGSOL bietet ein einzigartiges Ökosystem aus Logistiksoftware und Logistik- und Fabrikplanung. Seit über 20 Jahren entwickeln wir für unsere Kunden Lösungen für alle Bereiche der Logistik und Produktion entlang der Supply Chain.

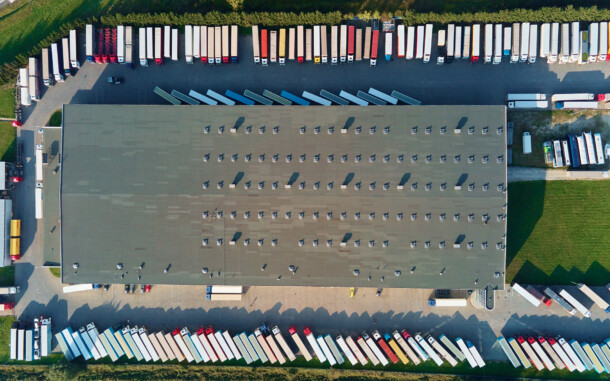

Logistik- und Fabrikplanung

Effizienz steigern und Kosten senken – mit professioneller Planung und Beratung von Experten.

Logistiksoftware

Flexible Softwarelösungen müssen entlang der Supply Chain verfügbar sein – trotz einheitlicher Standards.

Services

Die LOGSOL-Services vereinen unser übergreifendes Know-how, das wir in der Logistik- und Fabrikplanung sowie im Bereich der Logistiksoftware unterstützend einbringen können.

Unsere Logistikerfahrung in Zahlen

Projekte

international

Mitarbeitende

Stand 2024

Standorte

deutschlandweit

Projektstandorte

weltweit

Jahre

Logistikerfahrung

Stunden

Logistiklösungen pro Jahr

Software-User

weltweit

Planung von Leergutlieferungen mit BinMan®

Verglichen mit anderen ähnlichen Softwareprodukten stellt BinMan® eine intuitive und leicht anzuwendende Software dar, die dennoch alle Anforderungen der BMW Brilliance Automotive ltd. effektiv und vollständig abbilden kann.

Projektmanager Logistik, BMW Brilliance Automotive Ltd.

Behälterüberwachung mit BinMan®

Durch den Einsatz von BinMan® und den verschiedenen Funktionen konnten wir den Einsatz und die Verwaltung unserer Behälter deutlich effektiver und effizienter gestalten. Unsere Erwartungen sind daher voll erfüllt; auch mit der Gewissheit, bei möglichen Anpassungen einen Partner zu haben, der schnell auf unsere individuellen Anforderungen reagieren kann.

Logistikplaner, Robert Bosch GmbH

Werksintegration und Lagerumgestaltung bei MAHLE Behr

LOGSOL bot uns kurzfristig einen fachlich sehr versierten Logistikplaner an, der durch seinen Blick von außen noch zusätzlich Ideen für unser Projekt eingebracht hat. Vor allem aber überzeugt nicht nur die Theorie, sondern auch die wirklich tatkräftige Unterstützung bei der Umsetzung.

Leiterin Logistik, Werk Mühlacker, MAHLE Behr GmbH & Co. KG

Effizienzsteigerung an der Laderampe

Seit der Einführung des RampMan® konnten wir unsere Effizienz um ein Vielfaches steigern! Erhöhte Transparenz verbunden mit einer optimierten Planung ergeben für uns zahlreiche Vorteile in der internen Prozessstabilität sowie in der Lieferantenkommunikation.

Bereichsleiter SCM & Logistik, RASTAL GmbH & Co. KG

Einbindung mobiler Datenerfassungsgeräte mit BinMan®

Basierend auf einem Spezifikationsworkshop und den kommunizierten Anforderungen der DAF Trucks N.V., wurde von LOGSOL ein Lösungsvorschlag zur Abbildung aller Anforderungen im BinMan® 2.0 erstellt. Der Fokus des Kunden lag dabei insbesondere auf der Einzelbehälterverfolgung in Echtzeit sowie der Einbindung von mobilen Datenerfassungsgeräten.Weiterlesen

BinMan® App: KUIPERS technologies goes digital

Die App arbeitet im Alltag zuverlässig, anwenderfreundlich und bildet genau das ab, was wir als Anwender gewünscht haben. Durch die Reduzierung auf das Notwendigste, ist die Handhabung einfach und jedem Mitarbeiter zu vermitteln, sodass sich die Abarbeitung im Alltag deutlich beschleunigt.

Leiter Logistik/Disposition, KUIPERS technologies GmbH in Meppen

BinMan®: Individualentwicklung für Ehrlich Logistics GmbH & LOG ONE GmbH

[...] Uns fehlten Auswertungsmöglichkeiten und zeitnahe Kontoauszüge zur Abstimmung mit den Kunden, Fahrer und Fahrzeugsalden waren kaum prüfbar. Der Markt für solche Software war überschaubar, das Angebot eher flach. Mit LOGSOL fanden wir einen Partner, der mit uns gemeinsam auf Basis seiner Lösung „unser“ Palettenprogramm entwickeln wollte.

Geschäftsführer, Ehrlich Logistics GmbH

Produktionserweiterung @ Hitachi Astemo Europe GmbH

Mit dem Abschluss des Projektes übergab das LOGSOL Projektteam der Hitachi Astemo Europe GmbH einen Masterplan für die zukünftigen Entwicklungsmöglichkeiten am Standort Roßwein sowie eine Empfehlung aus den aufgezeigten Varianten. Zur Umsetzung der Vorzugsvariante unterstützte die LOGSOL GmbH Hitachi Astemo Europe bei der Feinplanung, Erstellung von Lastenheften, Ausschreibungsbegleitung von Technik und Outsourcing-Umfängen sowie der finalen Implementierung.Weiterlesen

Wie können wir Ihnen behilflich sein?

Newsblog

Zukunft gestalten: LOGSOL öffnet seine Türen in Chemnitz

2 Min. Unternehmen

Erleben Sie, wie LOGSOL am 11. April 2024 Innovation und Tradition in Chemnitz vereinte! Lesen Sie mehr über die inspirierenden Vorträge über Automatisierung und digitale Transformation der ...

Weiterlesen

Poleposition: thyssenkrupp Automotive Systems startet mit Fahrerlosem Transportsystem

3 Min. Logistik- und Fabrikplanung

Erfahren Sie, wie LOGSOL ein innovatives, fahrerloses Transportsystem (FTS) in nur einem Jahr bei thyssenkrupp Automotive Systems in Leipzig implementierte. Dieses ambitionierte Projekt im ...

WeiterlesenLOGSOL NEWS ABONNIEREN

und keine Neuigkeiten aus der Fachwelt, Projektberichte, exklusive Messeeinladungen und Insights verpassen!