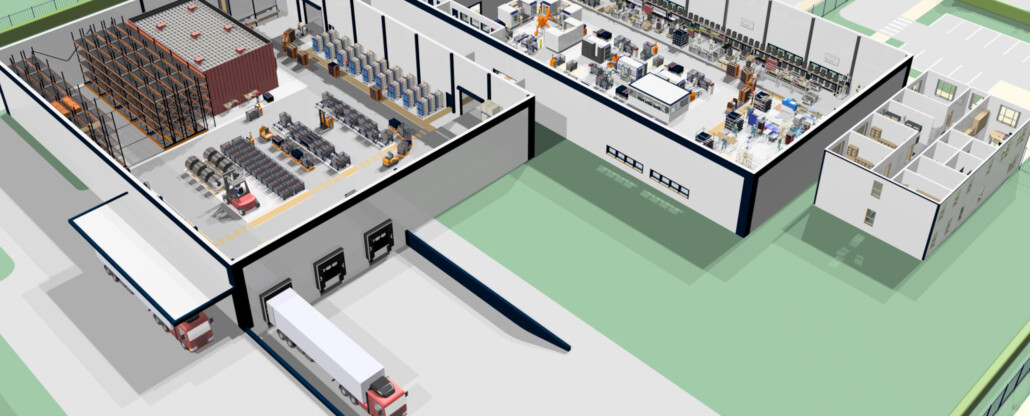

Logistics and factory planning

Lean processes and standardized procedures for waste-free working – LOGSOL develops

practical solutions for intralogistics and along the supply chain: from initial analysis and planning to simulation and implementation.

Our approach to logistics and factory planning

project definition

Together, we create a uniform project basis, taking into account logistical challenges, developments, and goals. In close consultation, we define work packages and milestones and create a roadmap before the project starts, enabling you to realistically assess potential and prospects for success.

planning

In rough and detailed planning, our team of experts first develops various concepts and then uses qualitative and quantitative criteria to derive a preferred option. If this option is particularly complex or dynamic, a simulation model is created for realistic validation to check the feasibility of the planned solution.

analysis

LOGSOL begins every project with an analysis. We gain a comprehensive understanding of your processes, create a uniform database, and examine the conditions on site.

This lays the foundation for all further planning steps.

implementation

We support you in tendering and procuring technology, in project management, in IT integration and commissioning—all the way to a stably implemented process.

even Logistics – Top-rated solution for planning, control, and digitization

Is your logistics planning future-proof? LOGSOL was named the “Best Rated Solution” in the field of logistics planning by the rating platform even. Benefit from our comprehensive planning expertise, which is based on the experiences of real users and enables sustainable, economical logistics concepts.

Customized solutions for different markets

Whether in commerce, industry, healthcare, or infrastructure, LOGSOL combines in-depth expertise with innovative approaches and tried-and-tested strategies. We understand the challenges specific to each industry as well as the relevant future trends, and use this knowledge to develop tailor-made solutions that optimize processes and increase efficiency.

Thanks to our experience in a wide variety of markets, we develop concepts that are convincing today and will stand the test of time.

More about our industry expertise

PMO & Project Management in Planning Projects

- Support in coordinating all work packages

- Ensuring management, administrative, and coordination tasks are completed on schedule

- Documentation of communication, escalation, and decision-making processes

- Organization and moderation of regular meetings

- Regular technical and financial progress reports

- Ongoing risk monitoring and escalation to management

- Establishing a common understanding and interfaces with sub-areas

- Quality and progress control in main and sub-projects

- Support with project documentation

The difference that makes the difference

With LOGSOL

- Years of expertise and successful projects

- Independent, neutral technology selection

- Individual, holistic concepts

- Efficient planning thanks to proven standards

- Knowledge transfer from comparable projects

Without LOGSOL

- Increased demand for time and resources

- Risk of unilateral technology selection

- Focus on general standard solutions

- In-house development of processes and tools

- Lack of cross-industry vision

Efficient brownfield planning: central logistics processes in the existing building

Brownfield planning of an existing building for the centralization of logistics processes from incoming goods to supply logistics and outgoing goodsRead more

Site planning and implementation

Development of an existing logistics location to integrate additional product ranges from other locations of the SSV-Kroschke GroupRead more

Logistics concept for hospital supply

Master planning of hospital logistics for the transformation of an urban hospital of the highest care class into a university hospital with a future-oriented campusRead more

Strategic depot network optimization & implementation: logistical concept study with PMO support

Consulting on the development of logistical concept studies to optimize a Germany-wide depot network - including support for the preferred solution as part of project management (PMO)Read more

SachsenEnergie SAP S/4HANA EWM preliminary project

Implementation of an SAP pre-project with the aim of drawing up specifications and a preliminary decision on the implemented SAP EWM variantRead more

Production simulation at B. Braun

Simulation of the entire production at the site to investigate various operating scenarios under the premise of maximizing output.Read more

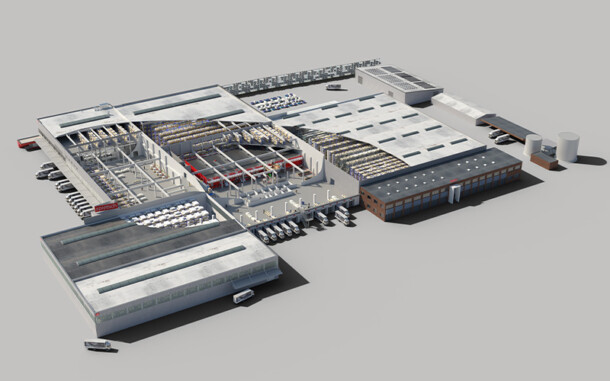

Site expansion and automation in the brownfield

Transformation of the central warehouse: from manual processes at the edge of capacity limits to a future-proof logistics center with custom-fit, integrated automation.Read more

Development of a holistic logistics strategy

Development of a holistic and sustainable logistics strategy 2028 to ensure the supply of the Leonding and Neidling production sites.Read more

Arrange a consultation appointment now!

For all questions around the topic logistics and factory planning I am at your disposal with pleasure!

Here you can find our privacy policy

Frequently asked questions about logistics and factory planning

How does a typical logistics and factory planning project with LOGSOL work?

Our consulting process is both structured and flexible. We start with a thorough analysis, develop a customized concept, and plan the implementation with clear milestones. LOGSOL actively supports you through to implementation—including performance review and fine-tuning for sustainable results.

What distinguishes LOGSOL project teams?

Experience, flexibility, and a hands-on approach—combined with target group-oriented communication and on-site presence.

How do we identify and minimize risks in logistics and factory planning?

LOGSOL identifies and minimizes risks in logistics planning through a thorough analysis of your supply chain and the processes involved. This includes assessing potential bottlenecks, downtime, security risks, and other disruptive factors.

By applying proven methods and industry-specific experience, we develop targeted measures to reduce risk.

In this way, we ensure reliable and resilient logistics planning that helps your company minimize potential risks and cope with unforeseen disruptions.

With LOGSOL as your partner, you enjoy the following advantages

Working with LOGSOL makes your job easier and gives you the security of a competent partner with extensive industry expertise, experience, and professional competence who is always there for you as a permanent point of contact.

We provide you with a professional assessment from an outside perspective, and you benefit from suitable solutions and a customized customer offer.

What are the current trends in logistics and factory planning?

Important trends include sustainability (green logistics), digitalization and the use of big data, supply chain resilience, and personalized logistics that adapt to individual customer needs.

What is the typical process for a planning project?

A project usually begins with an analysis phase, followed by conception, detailed planning, and implementation. The collaboration is modular in structure and can be flexibly adapted.

How can we effectively manage the complex dependencies in logistics projects?

Effective management of complex dependencies in logistics projects requires the application of a systematic approach that includes early identification, transparent communication, and consistent monitoring. It is crucial to use a central platform or tool for visualizing and controlling all interdisciplinary dependencies.