Supply chain management

Our planning professionals are specialized in the strategic design of the entire supply chain and in the provision of operational support to our customers.

Supply chain planning: analysis – planning – strategy

LOGSOL plans and implements custom supply chain concepts:

- Network planning and design

- Supply chain risk management

- Inventory optimization

- Transportation planning

- Planning of packaging/circulation

- Tender management for transportation services

Supply chain operations: realization – hypercare – control

LOGSOL’s experts will support you at an operational level:

- Material planning and bottleneck control

- Forecasting, budgeting, and reporting

- Freight cost management

- Interim supply chain management

- Supplier auditing

- Delivery quality and complaint management

Network design

By designing and optimizing a network, we create the most efficient solution for the supply chain.

- Data transfer and validation

- Analysis of transport requirements and restrictions for each transport relationship

- Aggregation of quantities per transport relationship

- Creation and evaluation of conceptual network scenarios (e.g. direct traffic, hub, milk run)

- Allocation of the optimum mode of transport per lane

- Business case calculation / cost calculation

- Documentation of the developed solution

Supply chain risk management

Short-term changes to processes along the supply chain represent a major challenge for many companies. In addition to changes in suppliers and customers, the causes for this can also be extraordinary, unforeseeable situations. These include natural disasters such as volcanic eruptions or hurricanes, as well as pandemics. This sometimes results in far-reaching changes in company processes. In order to remain competitive on the market and to keep the supply chain stable, the negative effects must be remedied as quickly as possible. Active risk management is an iterative process divided into five steps:

1. Risk strategy

2. Definition of risk

3. Risk analysis and evaluation

4. Risk Management

5. Risk monitoring and control

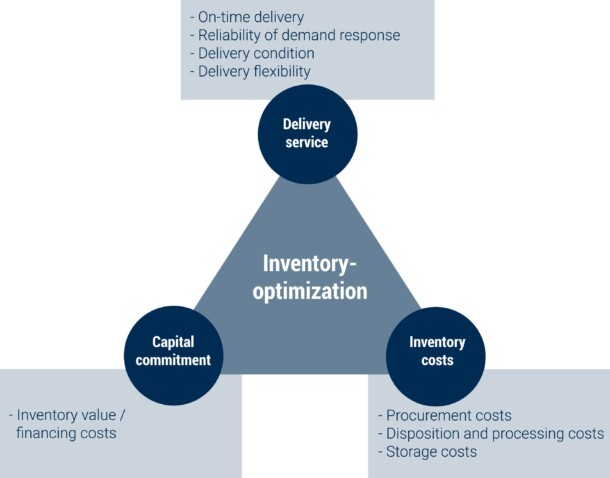

Inventory optimization

As experienced consultants in the field of inventory optimization, we offer solutions to perfect your warehousing in the long term:

- Diagnosis: Analysis of current stocks and their planning parameters and classification using ABC/XYZ or IQR.

- Planning: Creation of models for disposition and material planning as well as development of parameters for inventory planning.

- Realization: Implementation of measures to reduce inventories, implementation in the existing ERP system, and communication with those involved in the supply chain.

- Sustainable integration: Careful planning and implementation of inventory strategies enable continuous adaptation to changes in the market and internal processes.

Supplier management & auditing

We use the LOGSOL maturity model to audit suppliers. This enables potential risks to be identified at an early stage and preventive measures to be implemented. The audit is based on standardized questions within seven areas relevant to logistics:

- Communication

- Capacity management

- Material procurement

- Production planning

- Material flow

- Transportation

- Packaging

The aim of supplier management is to work with suppliers to identify problems and resolve them at an early stage.

Troubleshooting, bottleneck management, and material disposition

We also support you at an operational level to ensure successful supply chain management. In order to maintain the efficiency of your goods movement in the long term, we identify capacity bottlenecks in time and eliminate them. Particularly during special situations such as arrivals and departures, delivery performance can be poor. LOGSOL offers the following solutions to avoid this:

- Reporting: Transparent preparation of the supply/delivery situation and capacity utilization.

- Communication support: Supporting or coordinating with customers/suppliers as part of micromanagement.

- Bottleneck control: Support for scheduling tasks (e.g. material requirements planning, priority lists, transport control).

Efficient brownfield planning: central logistics processes in the existing building

Brownfield planning of an existing building for the centralization of logistics processes from incoming goods to supply logistics and outgoing goodsRead more

Site planning and implementation

Development of an existing logistics location to integrate additional product ranges from other locations of the SSV-Kroschke GroupRead more

Logistics concept for hospital supply

Master planning of hospital logistics for the transformation of an urban hospital of the highest care class into a university hospital with a future-oriented campusRead more