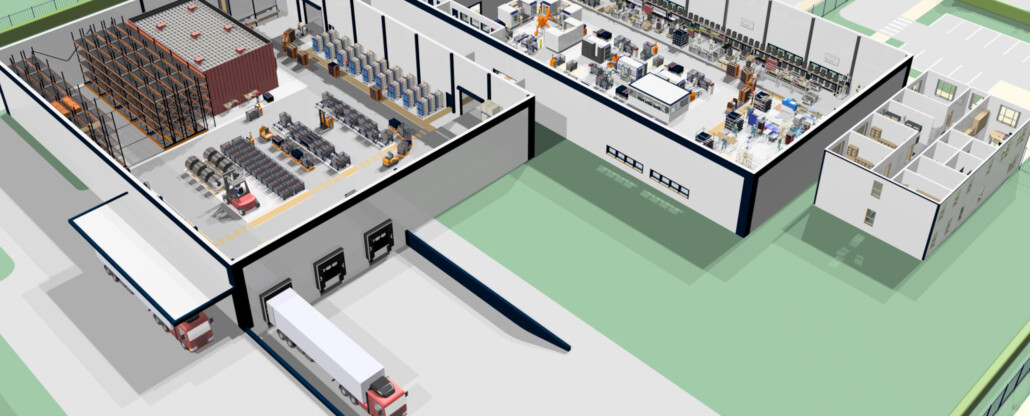

Logistics and factory planning

Lean processes and standardized workflows for waste-free work – LOGSOL develops practical solutions for intralogistics and along the supply chain: from the preliminary analysis and planning through to simulation and implementation.

Our approach to logistics and factory planning

Defining the project

Together with you, we create a coherent foundation for your project and consider logistical challenges, business developments, and goals set. We coordinate closely to define work packages and milestones. We draw up a roadmap for your individual project before the project starts. You can use this to realistically assess project potentials and chances of success.

Analysis

LOGSOL starts every project with an analysis. We gain a comprehensive understanding of your processes, create a standardized database, and consider the conditions on site. This lays the foundation for all further planning steps.

Planning

Our team of experts draws up various concepts in the rough planning phase. With the help of qualitative and quantitative evaluation criteria, a preferred variant is derived collaboratively. This will be developed further in the detailed planning phase.

Defining the project

Analysis

Planning

Simulation

Realization

Simulation

If the preferred variant is subject to particularly dynamic influences or if it is very complex, then the limitations of analytical methods quickly become evident. In order to realistically assess feasibility, we create a simulation model of the planned solution.

Realization

We support you in tendering and procurement of technology, in project management, IT integration, and commissioning – right through to the stable implementation of the process.

Efficient construction site logistics for your construction projects

Well-organized construction site logistics are the key to a smooth construction process.

LOGSOL supports you with perfectly coordinated logistics, well thought-out concepts and tried-and-tested solutions to ensure that your construction site is organized optimally, safely and sustainably.

This keeps your construction project on schedule and economically successful.

Find out more about construction site logistics

Optimized hospital logistics for your healthcare facility

This allows your staff to concentrate on the essentials: providing patients with the best possible care.

Find out more about hospital logistics

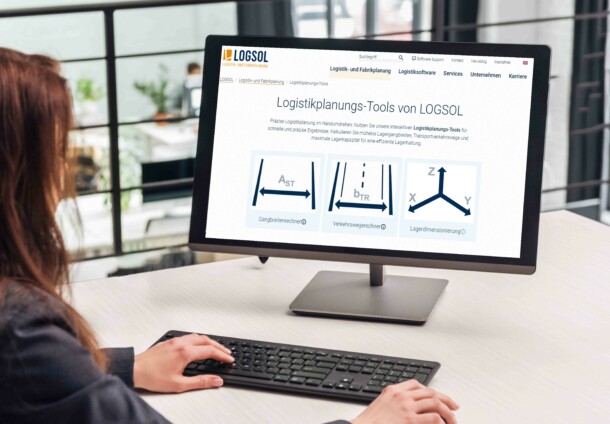

Logistics planning tools from LOGSOL

The tools that planners trust! At LOGSOL, we combine planning expertise with tailor-made software development!

Use our interactive logistics planning tools for fast and precise results. Use our three tools to calculate warehouse aisle widths, traffic routes and dimension your own warehouse.

Arrange a consultation appointment now!

For all questions around the topic logistics and factory planning I am at your disposal with pleasure!

Here you can find our privacy policy

Efficient brownfield planning: central logistics processes in the existing building

Brownfield planning of an existing building for the centralization of logistics processes from incoming goods to supply logistics and outgoing goodsRead more

Site planning and implementation

Development of an existing logistics location to integrate additional product ranges from other locations of the SSV-Kroschke GroupRead more

Logistics concept for hospital supply

Master planning of hospital logistics for the transformation of an urban hospital of the highest care class into a university hospital with a future-oriented campusRead more

Strategic depot network optimization & implementation: logistical concept study with PMO support

Consulting on the development of logistical concept studies to optimize a Germany-wide depot network - including support for the preferred solution as part of project management (PMO)Read more

SachsenEnergie SAP S/4HANA EWM preliminary project

Implementation of an SAP pre-project with the aim of drawing up specifications and a preliminary decision on the implemented SAP EWM variantRead more

Production simulation at B. Braun

Simulation of the entire production at the site to investigate various operating scenarios under the premise of maximizing output.Read more

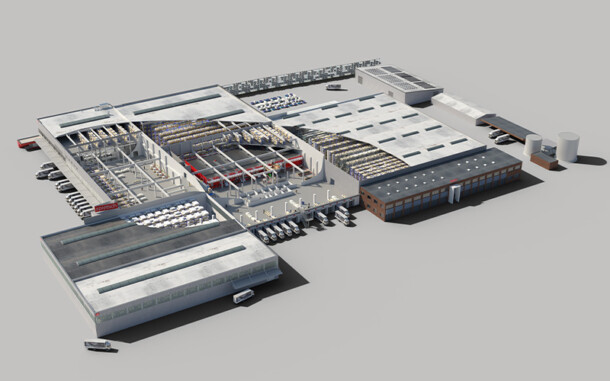

Site expansion and automation in the brownfield

Transformation of the central warehouse: from manual processes at the edge of capacity limits to a future-proof logistics center with custom-fit, integrated automation.Read more

Development of a holistic logistics strategy

Development of a holistic and sustainable logistics strategy 2028 to ensure the supply of the Leonding and Neidling production sites.Read more