AutoStore – from planning to go-live with LOGSOL

Are you planning to move your warehouse from manual processes to an automated future? LOGSOL is a certified consultant and will provide you with professional support in AutoStore planning and the implementation of your project. Rely on our expertise to revolutionize the future of your warehousing with AutoStore.

This is AutoStore

Improve your warehouse logistics with an automated small parts warehouse for more space and efficiency!

AutoStore is a highly automated storage and picking technology that has been implemented in over 1,400 facilities worldwide. Consisting of five key components, it forms an efficient system for optimizing order processing in various industries. Additional technologies such as barcode and RFID scanners, picking robots and packing lines can be integrated as required.

Bins

The AutoStore™ containers are stacked in the grid to save space. All goods are stored in these robust containers, which are available in three different heights. In order to organize several product categories in one container, it is possible to divide it into different compartments.

Grid

At the heart of the entire system is the aluminum frame. This not only forms the basic framework for the bins, but also acts as a support for the guide rail for the robots. The only requirement for this is a flat floor surface.

Robots

The AutoStore™ robots are extremely resilient. They move deftly, pick up containers and transport them to the respective workstations. These robots operate globally in both large and small teams. Their individual control ensures a high level of reliability, as there is no “single point of failure”.

Ports

The robots transport containers to the work stations of the AutoStore system, also known as ports. Orders are processed and stock levels replenished at these ports.

Controller

Traffic control. Stock monitoring. Control center. The AutoStore™ Controller always keeps an overview. It enables extended access control for service personnel and plans and schedules tasks.

See our AutoStore reference projects for yourself!

AutoStore System: Planning and realization by LOGSOL

There are many good reasons for LOGSOL to support your company in planning and implementing an AutoStore system:

Expertise and experience

LOGSOL is an expert in AutoStore projects and keeps an eye on technical aspects, schedules and costs for you. We are a trained AutoStore consultant and have extensive experience in the planning and implementation of automated warehouse systems for logistics planning.

Customized solutions

LOGSOL creates a customized AutoStore system that takes your specific processes and goals into account. Despite a high degree of standardization, the system is perfectly adapted to your requirements.

Together towards realization

We accompany you through the entire planning and realization process, from analysis to implementation. LOGSOL not only plans your AutoStore system, but also ensures seamless integration with other warehouse and business processes.

Cost advantages

Prices vary when system integrators are asked directly, which prevents competition in tenders. Thanks to LOGSOL’s consulting model, there is a uniform price basis that ensures fair competition between bidders.

Provider independence

Although AutoStore’s hardware is standardized, there are differences in the software and service provided by the integrators. We find and coordinate the best integrators for you and ensure comparable offers.

AutoStore alternatives

LOGSOL can also offer other available technologies, such as static storage solutions and ASRS (Automated Storage and Retrieval Systems). We will present you with suitable solutions and evaluate their effectiveness for you.

Your advantages of an AutoStore system

The AutoStore automated small parts warehouse offers you high storage density and flexibility in a small space. It enables fast order picking and uninterrupted 24-hour operation. Thanks to its modular design, expansions are possible without interrupting operations, saving you time and money. The closed system offers you theft protection and high energy efficiency, which leads to further savings.

Increased efficiency

Cost savings

Space optimization

Scalability

Shorter throughput times

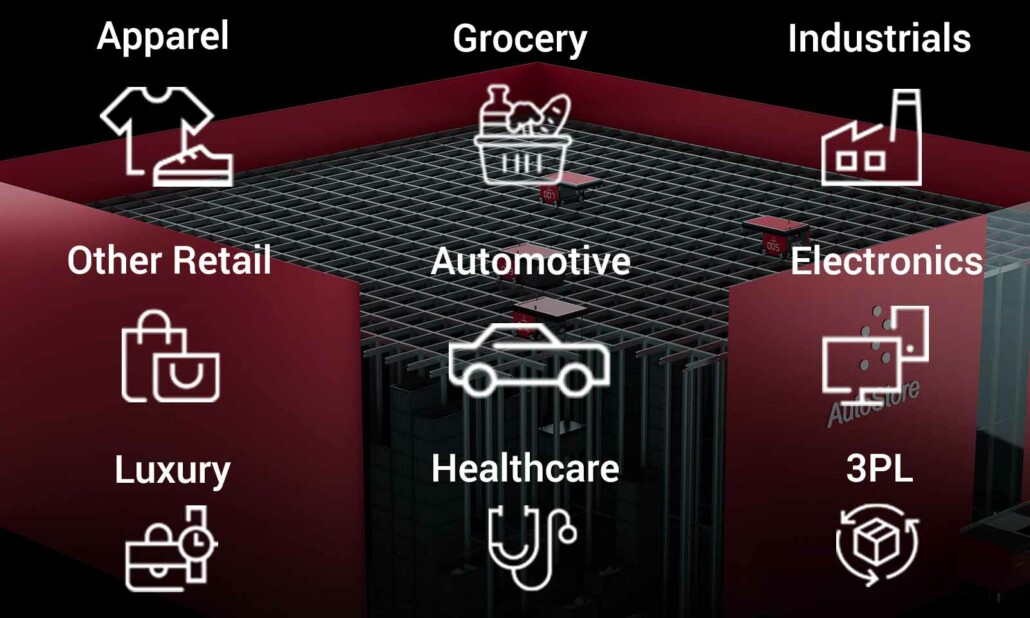

Where is AutoStore used?

AutoStore: Efficient logistics for various industries

AutoStore is revolutionizing warehouse and logistics processes worldwide, especially in e-commerce warehouses and distribution centers, through efficient storage and fast order processing.

An automated small parts warehouse handles high demands in online retail, supports production supply and enables efficient storage in the automotive and food industries, even in refrigerated systems down to -25 °C. This versatility makes it a powerful solution for many industries.

Arrange a consultation now!

I will be happy to answer any questions you may have about AutoStore and warehouse automation!

Here you can find our privacy policy