360-Grad-Logistik-Expertise

LOGSOL bietet ein einzigartiges Ökosystem aus Logistiksoftware und Logistik- und Fabrikplanung. Seit über 20 Jahren entwickeln wir für unsere Kunden Lösungen für alle Bereiche der Logistik und Produktion entlang der Supply Chain.

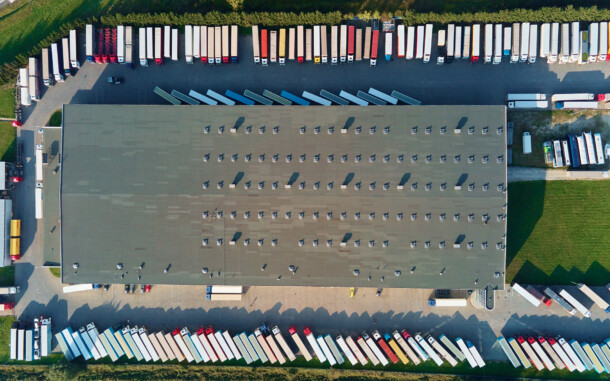

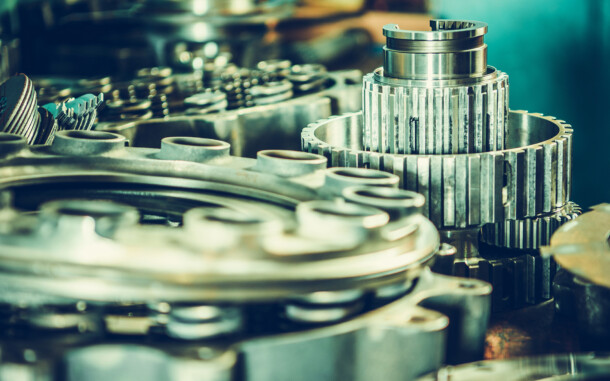

Logistik- und Fabrikplanung

Effizienz steigern und Kosten senken – mit professioneller Planung und Beratung von Experten.

Logistiksoftware

Flexible Softwarelösungen müssen entlang der Supply Chain verfügbar sein – trotz einheitlicher Standards.

Unsere Logistikerfahrung in Zahlen

Projekte

international

Mitarbeitende

Stand 2025

Standorte

deutschlandweit

Projektstandorte

weltweit

Jahre

Logistikerfahrung

Stunden

Logistiklösungen pro Jahr

Software-User

weltweit

RoutMan® als Komplettlösung

[...] Wir hatten auch die Möglichkeit, RoutMan®️ sowohl für bereits existierende Fälle zur Überprüfung unserer früheren Entscheidungen als auch für zukünftige Änderungen einzusetzen. Die Vorschläge, die wir von RoutMan®️ erhalten haben, erschienen interessant und nützlich. Jetzt haben wir genügend Zeit, um RoutMan®️ selbstständig zu verwenden und unsere anfängliche Einschätzung zu bestätigen.

Supply Chain Manager, Cooper Standard

Optimierung von Transportprozessen mit RoutMan®

Im operativen Bereich unterliegen unsere Routenverkehre im Inhouse-Bereich ständigen Änderungen und müssen daher regelmäßig (z. T. monatlich) angepasst werden. Mit dem RoutMan® haben wir ein Tool gefunden, mit dem die Anpassung der Planungen schnell und unkompliziert durchgeführt werden können und die Routen gleichzeitig optimiert werden. [...]

Competence Center Versorgungslogistik ∙ Business Development, Schnellecke Logistics AG & CO. KG

Effizienzsteigerung an der Laderampe durch optimiertes Zeitfenstermanagement

Seit der Einführung des RampMan® konnten wir unsere Effizienz um ein Vielfaches steigern! Erhöhte Transparenz verbunden mit einer optimierten Planung ergeben für uns zahlreiche Vorteile in der internen Prozessstabilität sowie in der Lieferantenkommunikation.

Bereichsleiter SCM & Logistik, RASTAL GmbH & Co. KG

BinMan® App: KUIPERS technologies goes digital

Die App arbeitet im Alltag zuverlässig, anwenderfreundlich und bildet genau das ab, was wir als Anwender gewünscht haben. Durch die Reduzierung auf das Notwendigste, ist die Handhabung einfach und jedem Mitarbeiter zu vermitteln, sodass sich die Abarbeitung im Alltag deutlich beschleunigt.

Leiter Logistik/Disposition, KUIPERS technologies GmbH in Meppen

Produktionserweiterung @ Hitachi Astemo Europe GmbH

Mit dem Abschluss des Projektes übergab das LOGSOL Projektteam der Hitachi Astemo Europe GmbH einen Masterplan für die zukünftigen Entwicklungsmöglichkeiten am Standort Roßwein sowie eine Empfehlung aus den aufgezeigten Varianten. Zur Umsetzung der Vorzugsvariante unterstützte die LOGSOL GmbH Hitachi Astemo Europe bei der Feinplanung, Erstellung von Lastenheften, Ausschreibungsbegleitung von Technik und Outsourcing-Umfängen sowie der finalen Implementierung.Weiterlesen

Werksintegration und Lagerumgestaltung bei MAHLE Behr

LOGSOL bot uns kurzfristig einen fachlich sehr versierten Logistikplaner an, der durch seinen Blick von außen noch zusätzlich Ideen für unser Projekt eingebracht hat. Vor allem aber überzeugt nicht nur die Theorie, sondern auch die wirklich tatkräftige Unterstützung bei der Umsetzung.

Leiterin Logistik, Werk Mühlacker, MAHLE Behr GmbH & Co. KG

BinMan®: Ressourcenschonung und Kosteneinsparung

Die Ziele flexibler Ladungsträger-Managementsysteme werden mit Nachdruck verfolgt. Hintergründe über die Einführung von BinMan® in einem der größten Baumaschinen-Handelsorganisationen der Welt waren u. a. Kriterien zur Ladungssicherung, Ressourcenschonung und für Kosteneinsparungen. Insbesondere die Reduktion von Transportschäden sowie eine bessere Witterungsbeständigkeit der Verpackungen sprachen für einen Einsatz von Mehrwegbehältern mit individueller Barcodelabelung anstelle anfälliger Einwegpackmittel.Weiterlesen

Behälterüberwachung mit BinMan®

Durch den Einsatz von BinMan® und den verschiedenen Funktionen konnten wir den Einsatz und die Verwaltung unserer Behälter deutlich effektiver und effizienter gestalten. Unsere Erwartungen sind daher voll erfüllt; auch mit der Gewissheit, bei möglichen Anpassungen einen Partner zu haben, der schnell auf unsere individuellen Anforderungen reagieren kann.

Logistikplaner, Robert Bosch GmbH

RoutMan® als Komplettlösung

[...] Wir hatten auch die Möglichkeit, RoutMan®️ sowohl für bereits existierende Fälle zur Überprüfung unserer früheren Entscheidungen als auch für zukünftige Änderungen einzusetzen. Die Vorschläge, die wir von RoutMan®️ erhalten haben, erschienen interessant und nützlich. Jetzt haben wir genügend Zeit, um RoutMan®️ selbstständig zu verwenden und unsere anfängliche Einschätzung zu bestätigen.

Supply Chain Manager, Cooper Standard

Optimierung von Transportprozessen mit RoutMan®

Im operativen Bereich unterliegen unsere Routenverkehre im Inhouse-Bereich ständigen Änderungen und müssen daher regelmäßig (z. T. monatlich) angepasst werden. Mit dem RoutMan® haben wir ein Tool gefunden, mit dem die Anpassung der Planungen schnell und unkompliziert durchgeführt werden können und die Routen gleichzeitig optimiert werden. [...]

Competence Center Versorgungslogistik ∙ Business Development, Schnellecke Logistics AG & CO. KG

Wie können wir Ihnen behilflich sein?

Newsblog

BinMan® und die Schweizerische Post: Die Erfolgsstory wird fortgesetzt!

2 Min. Logistiksoftware

Mit BinMan® optimiert LOGSOL das Gebindemanagement der Schweizerischen Post – agil, digital und zukunftssicher.

Weiterlesen

Masterplan Krankenhauslogistik Transformation vom städtischen Klinikum zur Medizinischen Universität Lausitz – Carl Thiem

3 Min. Logistik- und Fabrikplanung

Masterplan Krankenhauslogistik für die MUL-CT: LOGSOL plant das Versorgungskonzept der Modellregion Gesundheit Lausitz.

WeiterlesenLOGSOL NEWS ABONNIEREN

und keine Neuigkeiten aus der Fachwelt, Projektberichte, exklusive Messeeinladungen und Insights verpassen!